After a long time with no progress on the 787B project and many other distractions, I'm finally back working on parts for it!

Right from the outset, the main issue for me (and many others) was fitting a V8 into the car where there should really be a four rotor engine. Fast forward to the present day and I'm now experimenting with rotary engines and the various build combinations that are possible. I have a 1985 Mazda RX7 that came complete with an engine and a load of spare engine parts to get the ball rolling.

I have rebuilt the 12A two rotor turbo engine in my RX7 and a few others now, and whilst everything was dismantled I decided to measure and draw up all relevant parts. Back when I started this project the four rotor seemed almost unachievable not to mention very expensive. Having seen more people building these engines now though , I decided to give it a go myself

In the last year or so since buying the RX7 I have carried out the following research and design work:

- Draw up all relevant Mazda OEM engine parts including eccentric shaft, rotors, stationary gears, counterweights, thrust bearing packages, rotor housings, end and middle plates etc. I picked up some RX8 engine part as well for comparison.

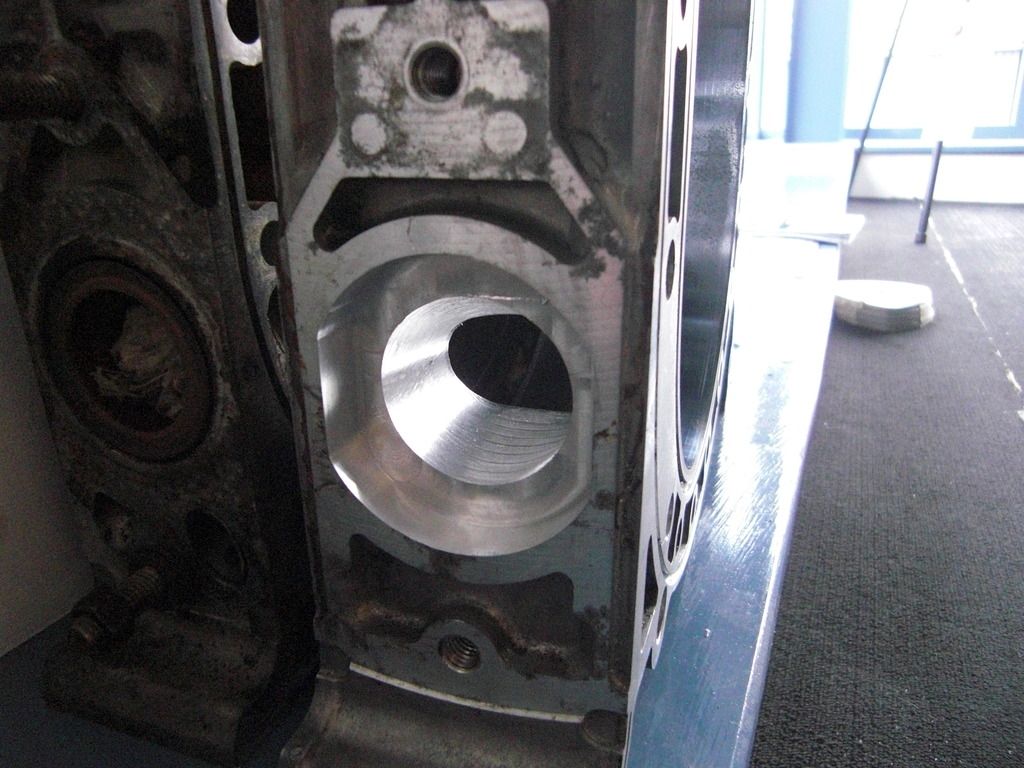

- Look into options for replacing worn out 12A housings, either by way of repair or creating new ones from donor 13B parts

- Peripheral porting experiments with worn out RX8 rotor housings.

- Draw up new designs for four rotor engine including eccentric shaft (5 piece), counterweights, main bearing housings, centre plate modification and direct oil feed system. I managed to gain access to a three rotor and four rotor shaft which I was able to measure up for reference.

Next on the list is to get together all the donor parts, and start machining the eccentric shaft now the material has turned up.

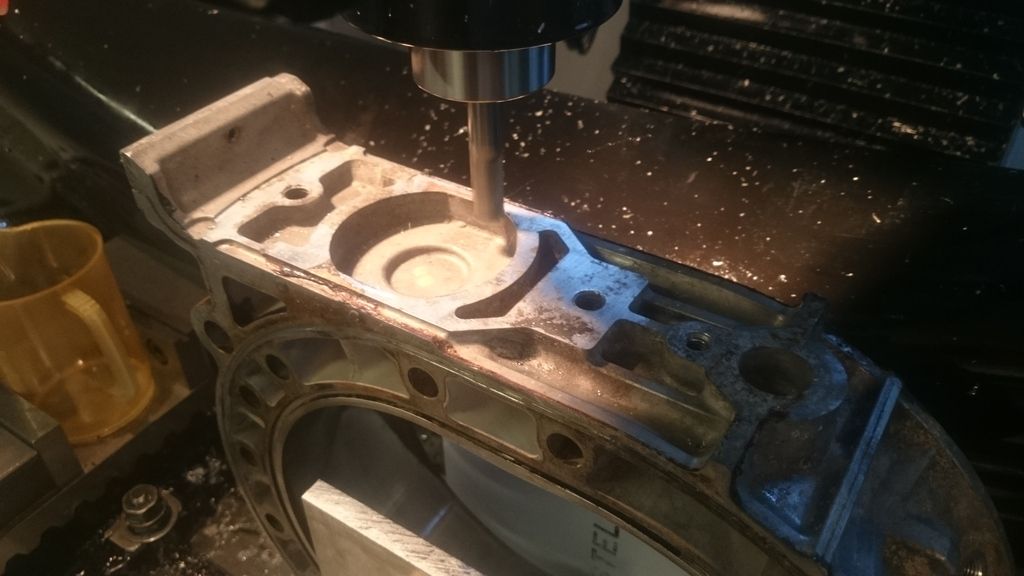

Here is a RX8 housing being machined to accept a steel exhaust sleeve: